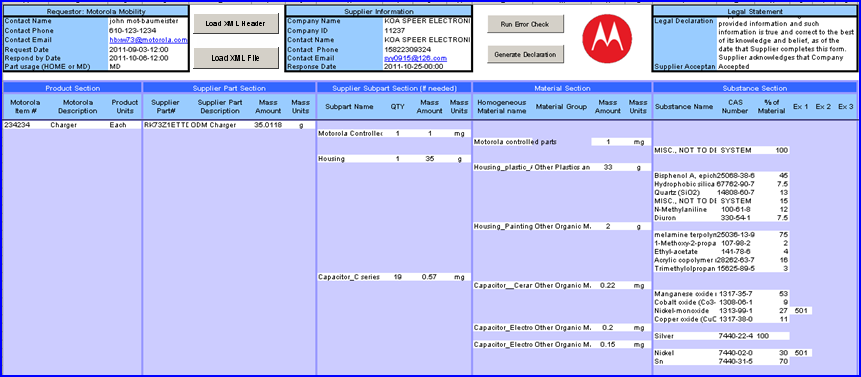

IPC - Material Data Entry for ODM Products

Click here to view this material in Chinese

Before entering the Material Data, the complete BOM combination is needed. Data entry for ODM Products begins with the same process outlined for Complex Assemblies:

|

|

- List the Motorola part numbers for the sub-parts which have Motorola part numbers

- Combine all the components with same materials

- The Combination BOM List will be sent as a supporting document to Motorola Mobility, the material data will be declared base on the combined parts

|

Example BOM for ODM Products

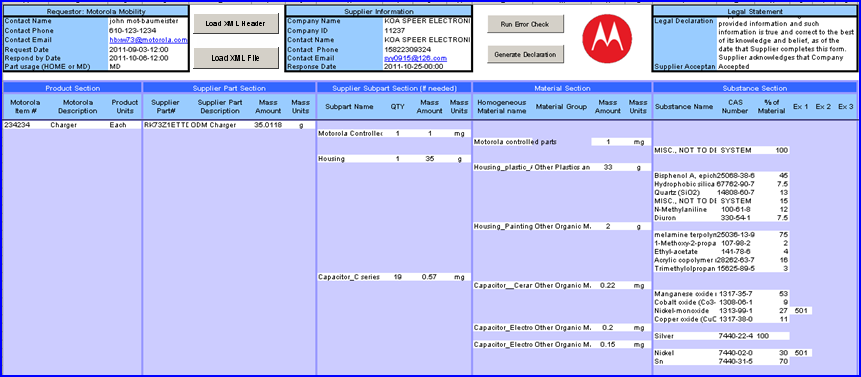

Entering Material Data:

-

Load a header file, and complete all required entries

-

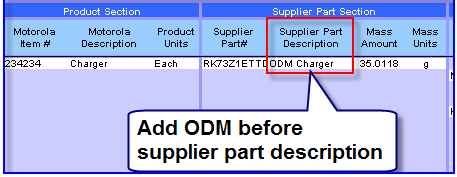

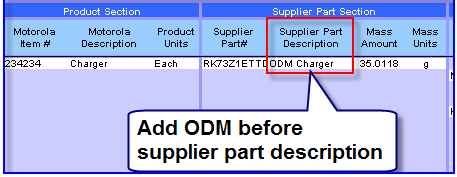

In the Supplier Part Section, add ODM before the Supplier Part Description: ex: ODM Charger

-

In the Row immediately following the Product row enter a unique Subpart Name

-

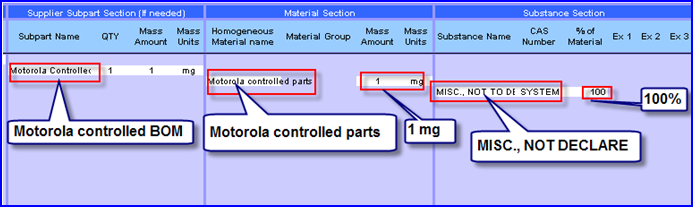

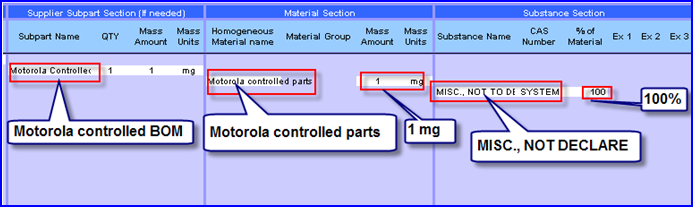

For the Motorola BOM controlled parts, list the Motorola part number in the Combination BOM List, then combine all the Motorola controlled parts into one item, declared as below:

|

Subpart name

|

Motorola controlled BOM

|

|

Homogeneous material name

|

Motorola controlled parts

|

|

Quantity

|

1

|

|

Mass

|

1mg

|

|

Substance name

|

MISC., NOT TO DECLARE (note space between comma and NOT)

|

|

CAS#

|

SYSTEM

|

|

% of Material

|

100%

|

-

-

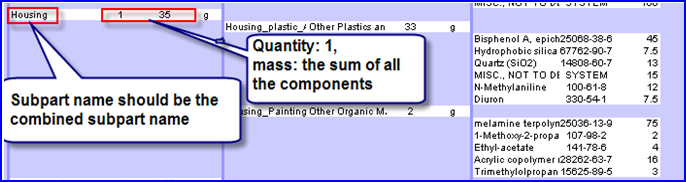

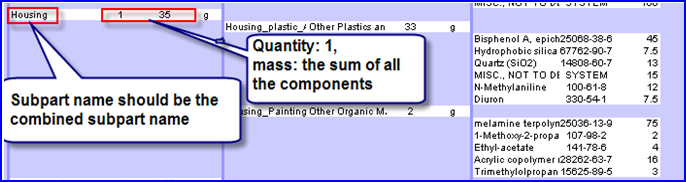

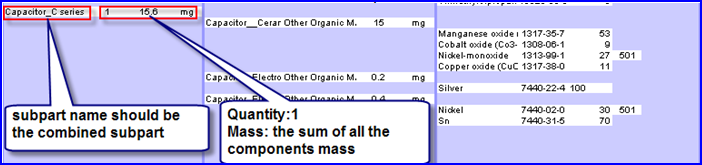

For ME parts, the subpart name should be the combined subpart name

Quantity = 1

Mass = the sum of all the components

-

-

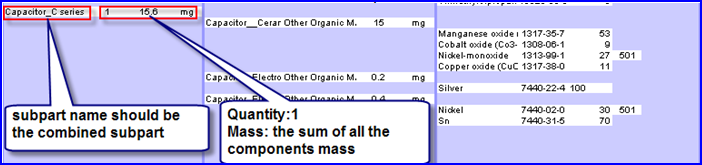

For EE parts, subpart name should be the combined subpart name,

Quantity = 1

Mass = the sum of all the components

-

-

For other not combined parts, follow the process outlined for Complex Assemblies and Single Component

Here is an example with one BOM controlled part, a ME part and a EE part

Return to the Motorola Mobility IPC Creator training material

![]()